Heat-resistant car insulation in the engine compartment

The challenge

For the most part, cars are insulated near to the engine. To do this, the adhesive must be flame retardant and able to withstand heat of up to 270 degrees. To avoid an orange peel effect on the non-woven materials, they must not shrink too much after cooling down. The components (especially at the edges) must be strongly bonded and must not open.

The path to our solution

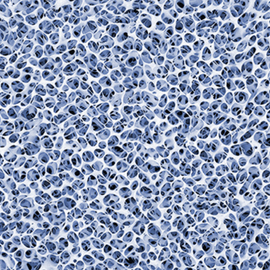

We are developing a thermoplastic powder mixture that is coated on the various non-woven materials at low temperatures. During the subsequent hot or cold pressing process, the materials are thermoformed as a sandwich with different substrates at around 200 degrees. Following this, the adhesive is cross-linked and extremely temperature-stable. There is no adhesive discharge or orange peel effect on the visible side or the back of the non-woven material.

The solution

Today we have around 20 different formulations in use, depending on the material structure and production process. Via the Tier 1 suppliers, we supply almost all of the large car manufacturers worldwide.

Informationen

Application

The following application technique was used for this project:

– Thermoforming (pressing)